Project Overview

Develop advanced mechanical rock breaking solutions in the Au and PGM mining industries.

Maintain and enhance production rates at minimised costs within a zero-harm value system

RAMMS is a joint initiative between

• Department of Mining Engineering, University of Pretoria and

• Department of Mechanical and Aeronautical Engineering, University of Pretoria

• Department of Geology and Mining, University of Limpopo

• Department of Earth Sciences, University of Venda

RAMMS is hosted by the Mining Resilience Research Centre (MMRC).

Research Thrusts

Rock cutting in narrow reef hard rock

Rock cutting offers significant potential advantages in mining. Although the underground soft-rock industry has converted almost completely to mechanized rock cutting, application in NRHR remains very challenging.

There are however important developments which could potentially contribute to more competitive cutting solutions for NRHR:

- Undercutting,

- Oscillation/activation,

- Improved cutters,

- Combined methods: Laser, High pressure water, Thermo-hydraulic.

There are also critical aspects that relate to the automation of the entire process, including:

- Following the reef

- removing material

Solving these problems is multidisciplinary. RAMMS combines its expertise in rock mechanics and mechanical structural integrity to develop a core research capability to deal with this problem.

A facility will be developed to measure the rock-cutter interactions, with the goal of establishing a fundamental understanding of rock-machine interactions and develop a platform for advanced research.

Schematic of new rock-cutter test facility

This will be done through studies focusing on:

- Various cutter studies: Attack angle, skew angle, depth, spacing Rock mechanics studies.

- Rock mechanics studies.

- Detailed finite element studies of forces and stresses in cutting equipment (rock materials models).

- Experimental analyses (strain gauges, stereo video photography).

Furthermore, investigation will take place on what are the most appropriate rock engineering parameters to determine cuttability of different reef types (e.g. which brittleness indices).

Performance optimization of mechanized equipment in narrow reef hard rock

Conventional NRHR mining processes entail drilling, blasting, cleaning and support and is a cyclic process. This poses serious challenges with respect to optimal use of equipment and management of people underground. Recent work has demonstrated that there is significant scope optimizing these processes based on simulation studies. RAMMS addresses this problem through development of probabilistic simulation models which take account of equipment performance and crew movements.

Utilisation, performance and condition monitoring of mining equipment in narrow reef hard rock

This is a very rich research environment which is relevant to mining production as well as equipment condition assessment. Developments in utilization, performance and condition monitoring of mining machinery take place in the context of a growing number of integrated (and increasingly interoperable) hardware and software solutions.

These solutions attempt to centralize data management, processing and in-shift decision making over the entire enterprise in vendor agnostic ways and in accordance to emerging standards. This is allowing third parties to interact with these systems and the data and produce subsystems or specialist algorithms that are optimized for specific circumstances.

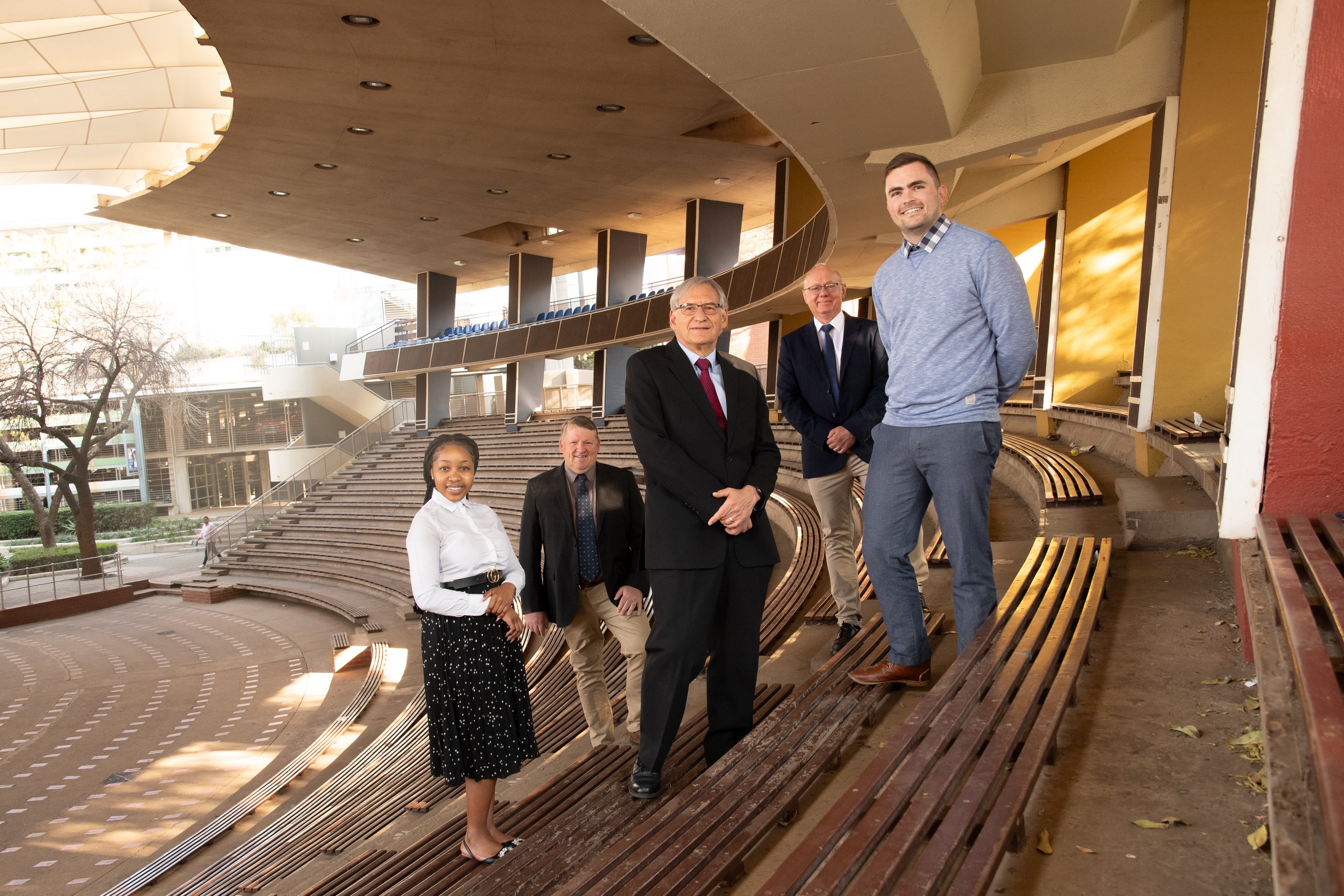

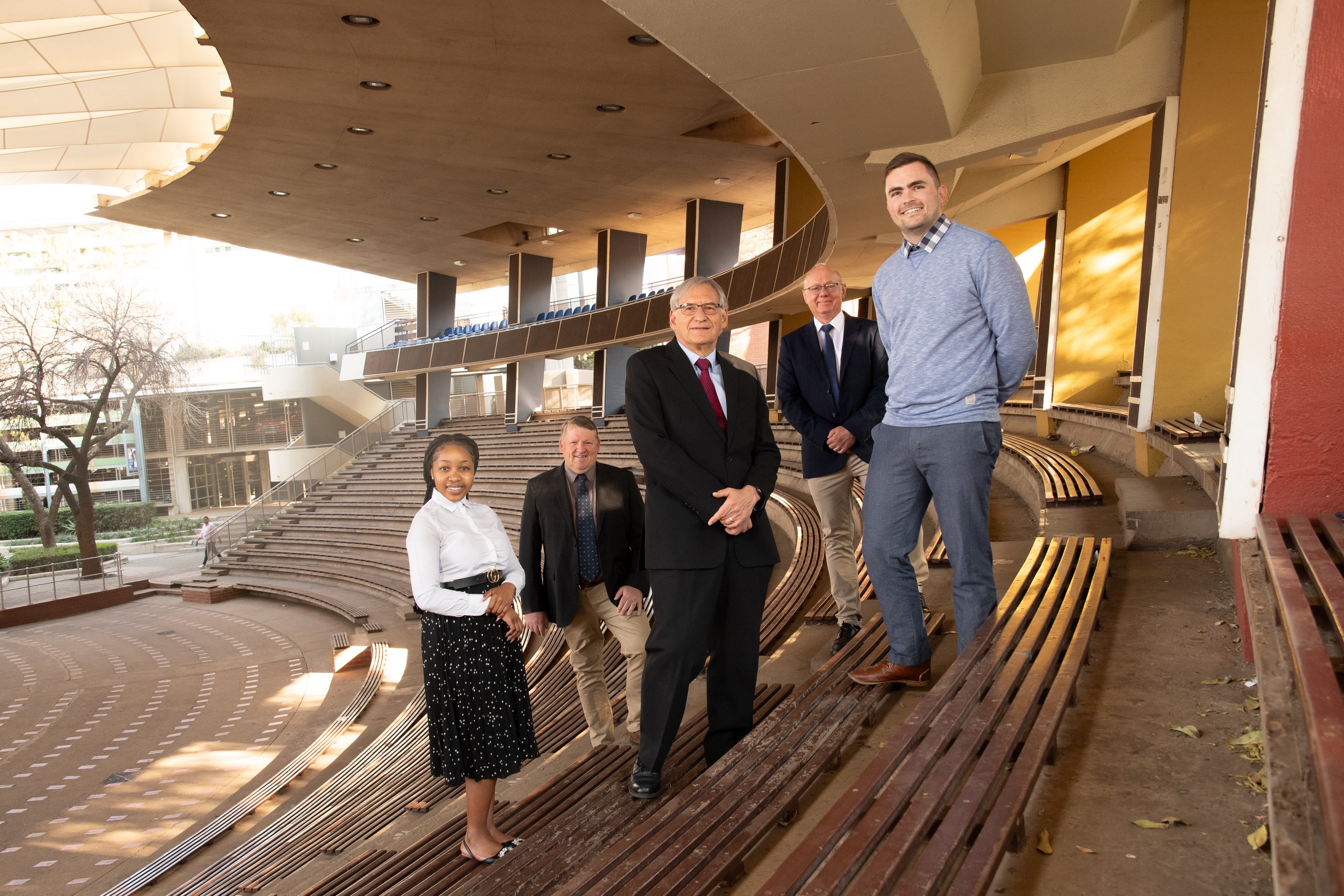

Personnel

The University of Pretoria team, from left to right: Ms Thobeka Masango, Prof Johann Wannenburg, Prof Stephan Heyns, Prof Francois Malan and Mr Luke van Eyk

|

Prof Francois Malan

Director of the Mining Resilience Research Centre (MRC), which hosts RAMMs

|

Prof Stephan Heyns

RAMMS Coordinator

|

|

|

| |

|

|

Dr Fhatuwani Sengani

University of Limpopo collaborator

|

Dr Milton Kataka

University of Venda collaborator

|

|

|

RAMMS Contact Details

Miss Thobeka Masango

[email protected]

+27 12 420 2096

Get Social With Us

Download the UP Mobile App