GEOTECHNICAL CENTRIFUGE LABORATORY

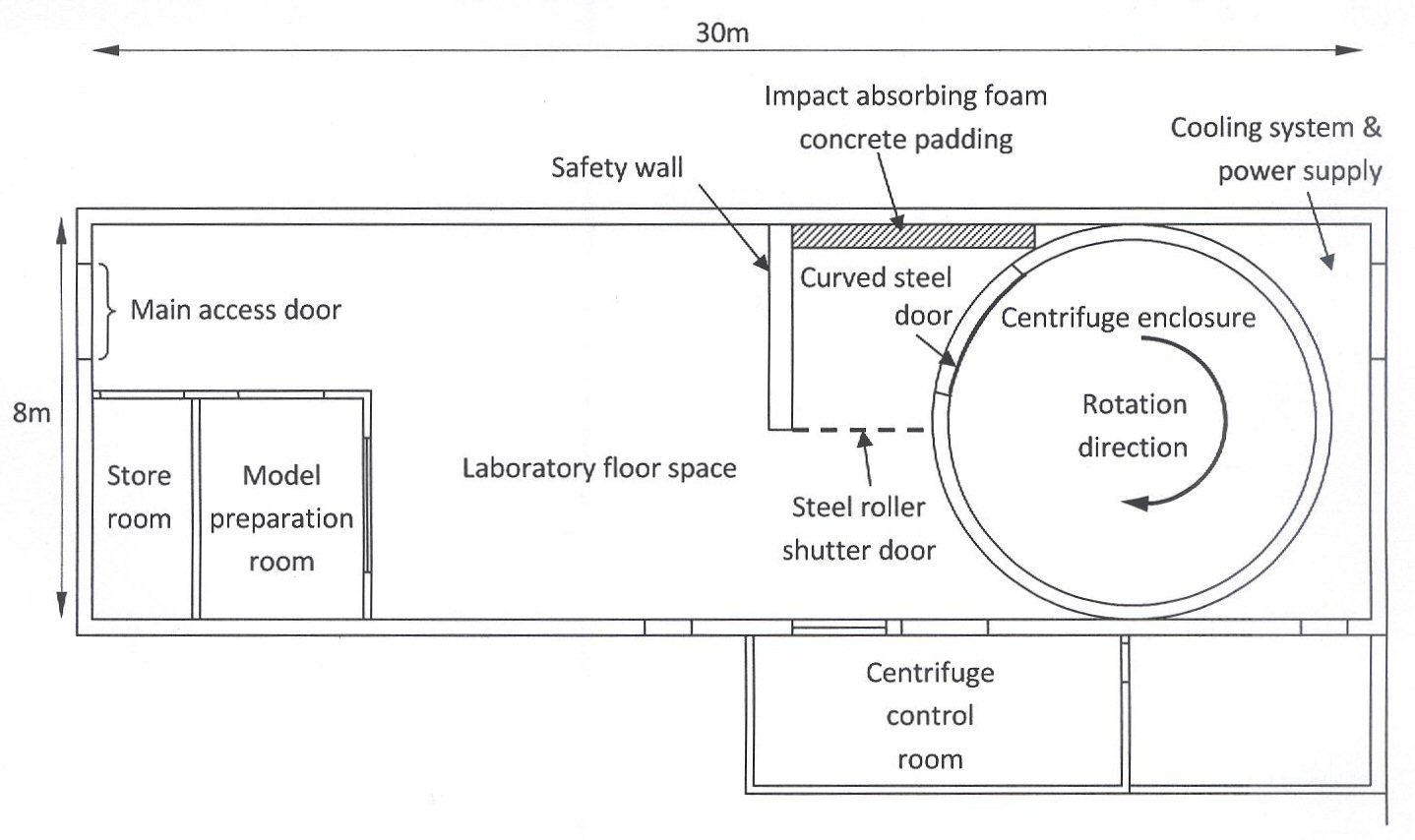

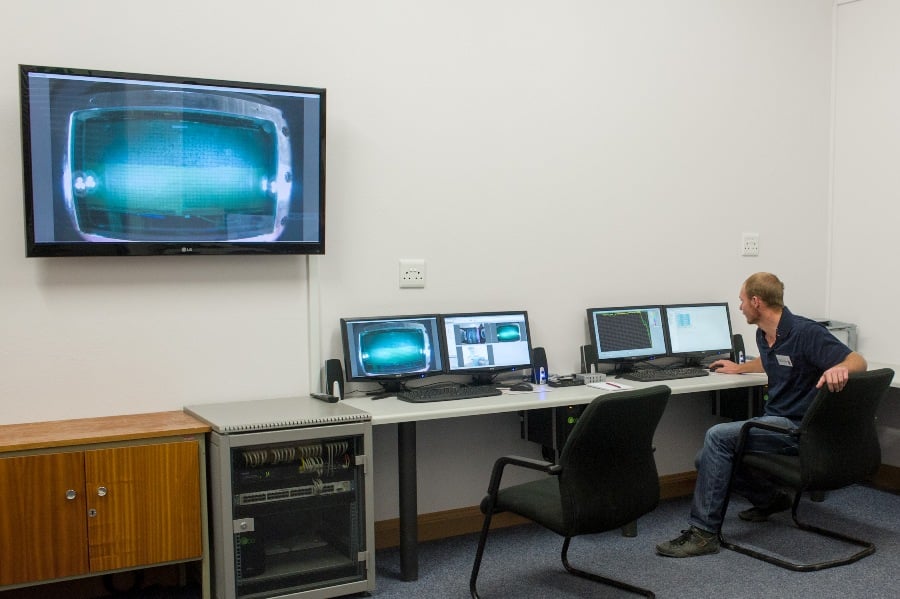

The Centrifuge Laboratory of the Department of Civil Engineering is located in the basement of Heavy Machine Laboratory B on the Hatfield Campus of the University of Pretoria. A schematic floor plan and a number of photos from the laboratory are shown below.

|

|

|

|

|

|

The centrifuge is a C67 Generation 4 geotechnical centrifuge manufactured by Actidyn, France, in 2011. The capacity is 150 g-ton, meaning that it is capable of accelerating a model weighing 1 ton to 150 g, or a model weighing 1.5 ton to 100 g. The model platform measures 1.0 m x 0.8 m with 1.3 m of head space. The radius to the model platform is 3 m. The centrifuge is equipped with electrical, hydraulic, pneumatic and water sliprings which support a wide range of actuators to be used on models.

Data acquisition systems comprise the German HBM system, complemented by the Digidaq system from the University of Western Australia. The data acquisition systems allow a wide range of instrumented to be monitored such as displacement and pressure transducers (piezometer and tensiometers) and acoustic emission detection sensors (which we have logged at up to 192 kHz) and Tekscan TM pressure mats. We also make use of fibre optic strain measurement using Bragg gratings on the centrifuge.

Data is transmitted to the control room via a fibre optic rotary link which eliminates electronic noise associated with traditional electric sliprings. Models are observed using a range of web cam based cameras in addition to a high resolution DSLR camera and a mono-chrome highspeed camera. The centrifuge is fitted with two solid state computers to manage data acquisition, actuator control and the cameras.

With our post graduate students we have developed a few in-house micro-computer controlled actuators and control systems for a range of centrifuge test purposes as described in the papers below:

BROEKMAN, A., JACOBSZ, S.W., LOUW, H., KEARSEY, E.P., GASPAR, T.A.V. and DA SILVA BURKE, T.S. 2020. Fly-by-Pi: Open source closed-loop control system for geotechnical centrifuge testing applications. HardwareX 8 (2020). Elsevier. https://doi.org/10.1016/j.ohx.2020.e00151

BASSON, J.A., BROEKMAN, A. and JACOBSZ, S.W. 2021. A low-cost data acquisition system monitoring the unsaturated pore pressure regime in tailings dams. HardwareX 10 (2021). Elsevier. https://doi.org/10.17605/OSF.IO/H9VBE.

A number of actuators / instruments have been developed as listed below:

For more information about the geotechnical centrifuge or for potential collaboration please contact Prof SW Jacosbz.

Copyright © University of Pretoria 2025. All rights reserved.

Get Social With Us

Download the UP Mobile App